Snack Dryers

Drying is an essential step in extruded snack food production. Accurate and even drying is paramount to ensure efficient and repeatable results.

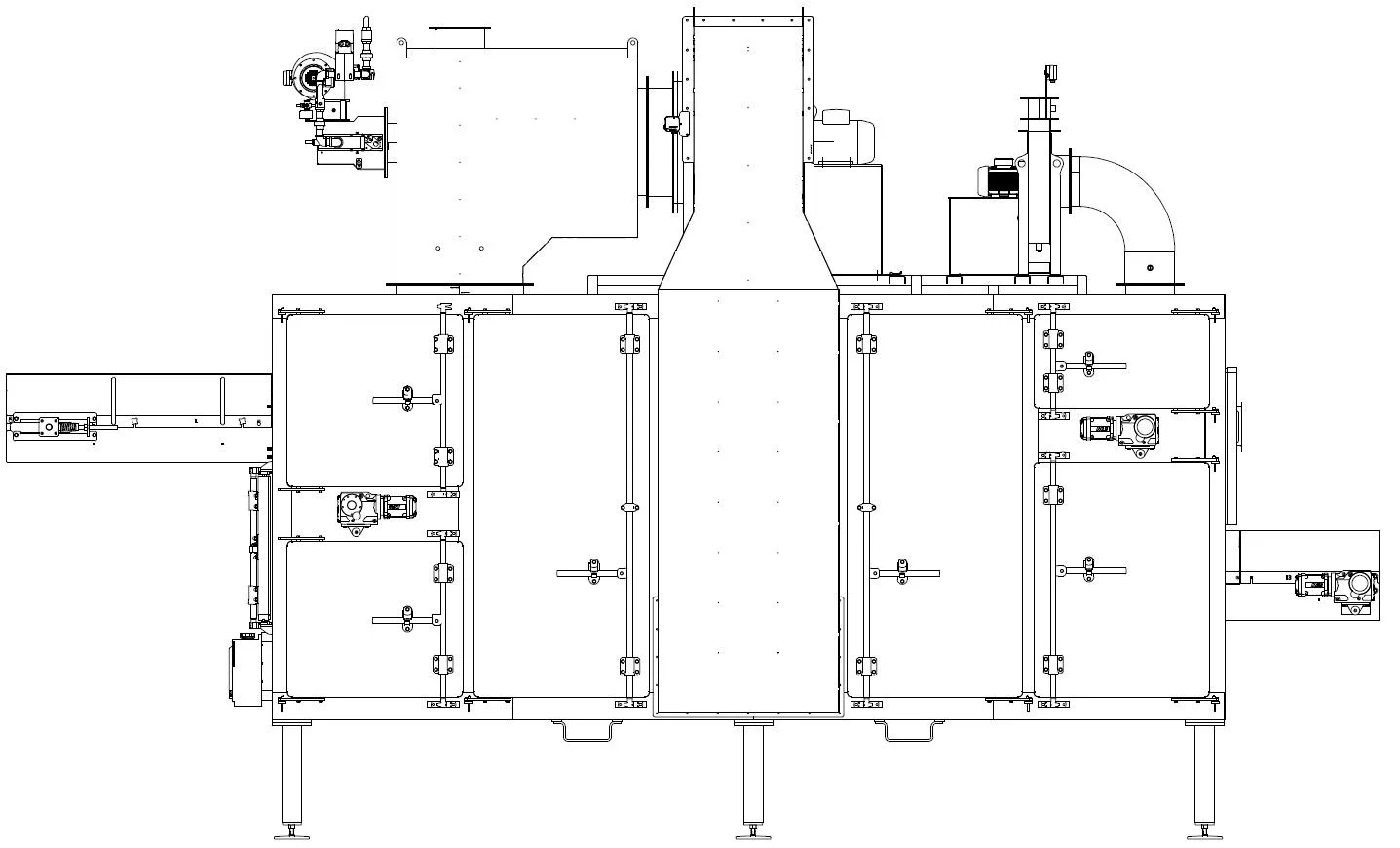

The CABE Tri-Pass Dryer is designed with the needs of modern snack food production in mind, encompassing key features for ease of operation, cleaning & maintenance.

This series is available in different sizes to suit the particular line capacity

Full 304 stainless steel construction, and sloped floor as standard.

Our unique approach brings:

Large dryer airflow management on a small scale

The ‘Box within a Box’

Efficiency

Energy & Efficiency are top of most agendas, which is where ‘Box within a Box’ comes in. Traditionally a dryer has an insulated housing which serves many purposes, namely, providing structure, guiding and sealing the process air path and containing thermal insulation.

The Tri-Pass housing contains an ‘inner box’ which takes on some of the above tasks. Conveyor & conveyor shaft support is handled by the inner box. No more hot shafts protruding outside the housing causing undesirable leakage or rotating snag points.

The process air path is guided and primarily sealed by the inner box, while the outer housing of the dryer provides thermal insulation and secondary sealing.

Sounds complex? Not really. Access is from the side doors, with ‘inner box elements’ being easily removed for access and cleaning. No complex air guides, just open space. No more struggling to remove components via end doors.

Want to do a deep clean? Easy. Open the side doors, pull out upper and lower plenum sheets and unfasten the conveyor side guides. We’ve even permanently numbered each part to make re-assembly easy and repeatable.

Need to replace a shaft? Easy. Opening a side door reveals generous access to the shafts and bearings. All shafts can be removed from the side.

Need to replace door seals? Easy. The seal is a push fit onto the door edge. No silicone sealant, no messy removal or re-fitting. No more putting off replacing tired door seals, that cause inefficiency.

Tri-Pass Models

-

Nominal Output

375kg/h

Outline Dimensions

7025mm x 2265mm x 4255mm

-

Nominal Output

550kg/h

Outline Dimensions

7025mm x 2465mm x 4255mm

-

Nominal Output

1000kg/h

Outline Dimensions

8935mm x 2660mm x 4380mm

-

Nominal Output

1200 kg/h

Outline Dimensions

1044mm x 2660mm x 4380mm

Process

The Tri-Pass Dryer consist of three conveyors that carry product through the dryer housing. A packaged heating system manages the airflow through the dryer.

Product is presented onto the top conveyor. The product passes along the top conveyor and cascades by gravity down onto the middle conveyor before passing back along through the dryer housing. The product passes onto the lower conveyor for it’s final pass through the dryer housing before being discharged at the end of the conveyor.

Process air is heated in the upper chamber of the dryer, before being drawn into the circulating air fan. The air is then delivered to the lower plenum where it is evenly distributed before passing up through the product on the conveyors.

As the air passes through the product it imparts heat to the product and picks up moisture from the product, before being drawn into the upper plenum chamber. From the upper plenum a controlled proportion of moisture laden air is drawn into the exhaust fan, and the balance passes to the heating chamber where it mixes with fresh air and is heated to setpoint before starting the cycle once more.

Accessories

Infeed vibrating conveyor (scarfed)

Discharge conveyors

Flavouring Systems

Cutters

Cleaning & Maintenance

Any piece of equipment on the factory floor has to be easy to operate and maintain. At CABE these features are core to our designs:

Superior access from sides for cleaning all areas of housing

Removable upper and lower plenums

Sloped floor

Heat Sources

-

Gas burner

-

Electric heating

Thermal Hot Oil

Our Latest Tri-Pass Dryer Projects

Contact Us

If you'd like to find out more about any of the products or services offered by CABE, don't hesitate to get in touch with us today.

Call one of our team members on +44(0)116 276 0938, send us an email via enquiries@cabeengineering.com or complete our contact form.